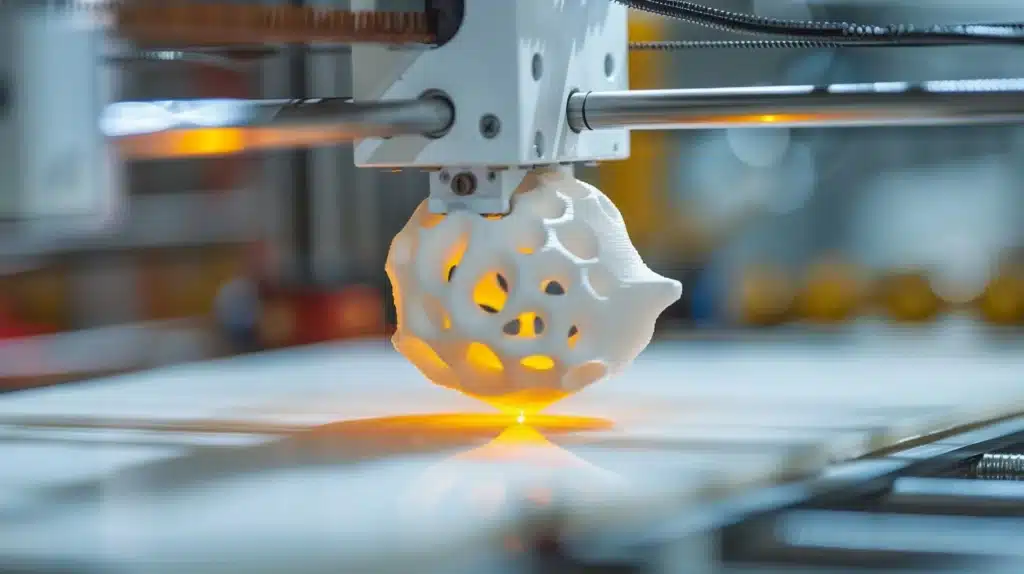

How 3D Printing Is Changing Product Design and Manufacturing

3D printing represents a significant shift in product design and manufacturing. This technology streamlines the prototyping process, allowing for swift iteration and immediate feedback. Additionally, it offers cost-effective production methods that reduce material waste. The ability to customize products on a mass scale enhances consumer engagement and fosters innovation. As the industry adapts to these changes, understanding the implications of 3D printing on traditional practices becomes essential. What challenges and opportunities lie ahead?

The Evolution of Product Design Through 3D Printing

As the demand for customized products has surged, 3D printing has emerged as a transformative force in product design, reshaping traditional methodologies. This technology enhances design accessibility and democratizes digital fabrication, allowing creators to produce intricate designs without significant investment. Consequently, designers can explore innovative concepts, tailoring products to individual needs while fostering a culture of creativity and freedom in the manufacturing landscape.

See also: Exploring the Technology Behind Streaming Services

Enhancing Prototyping and Iteration Speed

The integration of 3D printing into product design significantly accelerates the prototyping and iteration processes, enabling designers to move from concept to physical model with unprecedented speed.

Rapid prototyping allows for immediate design feedback, fostering a dynamic environment where ideas can be tested and refined swiftly.

This innovative approach not only enhances creativity but also empowers designers to explore multiple iterations efficiently, ultimately leading to superior products.

Cost Efficiency and Waste Reduction

Cost efficiency and waste reduction are among the most significant advantages of incorporating 3D printing into product design and manufacturing.

This technology facilitates material savings through additive processes, where only the necessary amount of material is utilized.

Furthermore, it enhances production scalability, enabling companies to adapt quickly to market demands while minimizing excess inventory and environmental impact, aligning with a commitment to sustainable practices.

Customization and Personalization in Manufacturing

While traditional manufacturing often relies on standardized processes that limit design variations, 3D printing revolutionizes customization and personalization in product development.

This technology enables mass customization, allowing manufacturers to adapt products based on unique consumer preferences.

Conclusion

In conclusion, the intersection of 3D printing with product design and manufacturing signifies more than mere technological advancement; it reflects a serendipitous alignment of creativity and efficiency. As designers harness rapid prototyping and customization, they inadvertently cultivate a culture ripe for innovation. This unplanned synergy not only reduces material waste but also democratizes production, enabling unique consumer experiences. Thus, 3D printing stands as a testament to how coincidental advancements can reshape industries, forging a sustainable future.